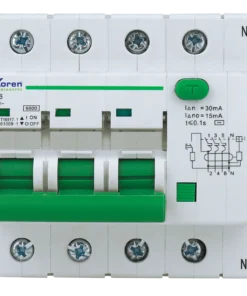

Technical Specifications:

Number of Poles: 4P

Short Circuit Breaking Capacity Icu: 50kA, 70kA

Icu = Ics 75%

Rated Current: Up to 400A

Rated Impulse Withstand Voltage: 8 kV

Fixed Type, Coil / Coil tripping

Protection Threshold: 100mA, 300mA, 500mA

Flameproof BMC body

Undervoltage coil, trip coil, auxiliary contact, alarm contact, motor control mechanism, mechanical lock, extended rotary handle, phase curtain accessories.

Function of Molded Case Circuit Breakers with Residual Current Protection

Molded case circuit breakers with residual current protection are important safety elements that protect both people and equipment by detecting leakage currents in electrical systems and automatically cutting the circuit. In electrical systems, under normal conditions, all electrical current must flow in a balanced manner between the phase and neutral in the circuit. However, in the event of any leakage, this balance is disrupted and molded case circuit breakers with residual current protection instantly detect this situation and cut the circuit. This function provides effective protection, especially against electric shock, fire risk and damage to devices.

These switches prevent leakage current from passing through the human body and have a role in preventing serious injuries or deaths that may occur due to electric shocks. At the same time, they prevent damage to the system in cases of overload and short circuits in the electrical system. Therefore, they are of vital importance in terms of safety and minimize system interruptions in industrial and commercial systems.

Usage Areas of Compact Switches with Leakage Current Protection

Molded case circuit breakers with residual current protection have a wide range of uses and are used to provide critical protection in many different sectors. They are widely used in domestic, commercial and industrial areas. While they are used to reduce the risk of electric shock in homes, they are also used to ensure energy efficiency and safety in large industrial facilities. Molded case circuit breakers with residual current protection stand out as indispensable safety equipment, especially in production lines, machine facilities, data centers and power plants.

In environments where there is a lot of contact with humidity and water, the use of these switches becomes even more important. Especially in areas such as pools, bathrooms, laundries, and commercial kitchens, these switches provide greater protection against the risk of leakage current. They are also widely used in construction sites, the agricultural sector, and renewable energy systems. In these areas, the use of leakage current protected switches is of great importance for the long-term operation of devices and the reduction of maintenance costs.

Advantages of Molded Case Circuit Breakers with Residual Current Protection

Residual current protected compact switches offer many advantages and these advantages are one of the main reasons for their widespread use. First of all, they prevent electric shocks and reduce the risk of fire by ensuring human safety. These switches help prevent major dangers such as fire by closing the circuit in seconds in the event of a leakage current. Especially in areas where electrical appliances are widely used, a safe environment is provided thanks to leakage current switches.

These switches also play an important role in terms of energy efficiency. They prevent damage to systems in cases such as overload or short circuits, thus minimizing both energy losses and failure costs. They also extend the life of devices and electrical systems, saving on maintenance and repair costs. Another advantage is ease of installation and use. Thanks to their compact structure, they can be easily installed even in limited spaces and automatically protect the circuit without requiring user intervention.

Installation of Compact Switches with Leakage Current Protection

Correct installation of residual current protected compact switches is extremely important for safety. The most important factor to consider when installing these switches is to choose a switch with a capacity suitable for the electrical system used. Since each electrical system has different characteristics, the needs of the system should be analyzed correctly before installation. Factors such as which circuit the switch will be used in, how strong the electrical current is, and how many electrical circuits there are in the system should be taken into consideration.

It is recommended that the installation be done by a professional electrician, because if the installation is incorrect, there is a risk that the switch will not work properly. In addition, the characteristics of the environment in which the installation will be made are important. Switches that will be used in humid environments or in places where there are extreme hot-cold differences must be resistant to these conditions. During the installation of the switch, leakage current testers should be used to ensure that the installation is correct.

Types of Compact Switches with Leakage Current Protection

Molded case circuit breakers with residual current protection are produced in different types and models. This variety allows the right product selection according to the needs of electrical systems. While single-phase switches are generally used for small residences and offices, three-phase switches are preferred for larger electrical circuits such as industrial facilities. These switches, which also have different types in terms of current capacity, can be used in a wide range from low-power electrical systems to high-power industrial systems.

Residual current circuit breakers can also be equipped with additional functions. For example, some models come with additional safety measures such as short circuit protection and overload protection. Such models offer a safer and more durable structure, especially in large electrical circuits. In addition, some models are equipped with technologies such as remote monitoring and control, so that residual current situations can be managed more quickly and effectively.

Maintenance of Molded Case Circuit Breakers with Residual Current Protection

Regular maintenance of residual current protected compact switches is critical to ensure the longevity of the switch and to ensure its safe operation. During maintenance, the switch should be checked for proper operation, overheating or mechanical damage. In addition, the connection points inside the switch should be cleaned and loose parts should be tightened.

Regular tests should be performed to determine if the circuit breaker’s leakage current protection mechanism is working properly. During these tests, the circuit breaker is checked to see if it is breaking the circuit at a certain leakage current level. Depending on the results of the tests, the circuit breaker may need to be repaired or replaced. Regular maintenance by a professional technician ensures the safe operation of the circuit breaker and minimizes potential hazards in electrical systems.

Fault Detection Methods of Molded Case Circuit Breakers with Leakage Current Protection

Various methods are used to detect faults that may occur in molded case circuit breakers with residual current protection . If the circuit breaker takes longer to cut off or if the circuit breaker does not cut off, this may be a sign of a fault. In fault detection, residual current testers are generally used. These devices check whether the circuit breaker closes the circuit correctly at the specified residual current levels.

In addition, physical inspection of the switch is important. If there are burn marks, cracks or signs of overheating on the switch, this may indicate that the switch is faulty. Faulty switches should be replaced immediately because if these switches do not work properly, serious risks to electrical systems can occur. If it is not possible to repair the switch after the fault is detected, the safest solution is to replace it with a new one.

Importance of Molded Case Circuit Breakers with Residual Current Protection in the Industry

The importance of residual current protected compact switches in the industry is quite great. In industrial facilities, the risk of leakage current is higher because large electric motors and machines are constantly operating. For this reason, residual current protected switches are of vital importance in such facilities. They both protect human life and prevent damage to electrical systems.

Especially in production lines, leakage current protected compact switches are used to ensure the safe operation of machines and to prevent possible failures. These switches prevent interruptions in the production process, increase the efficiency of businesses and minimize possible losses. In addition, they contribute to the reduction of maintenance costs in the industrial field and help production processes continue smoothly.