Technical Specifications:

Rated Voltage: 400 VAC

Rated Current: Up to 630A

Short Circuit Breaking Capacity: 85 kA

Rated Insulation Voltage: 1000 VAC

Rated Impulse Withstand Voltage: 8 kV

3 phases opening together or separately

Coating Type: Sn

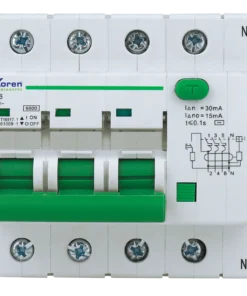

Horizontal Type Fuse Load Disconnectors

X Koren Electric Horizontal Type Fuse Disconnectors are used to protect the circuit in overcurrent and short circuit situations, where the fuse and switching mechanism are aligned on a horizontal plane.

Technical Specifications:

Rated Current: Up to 400A

Cutting from two separate points in phases

Usage Class: AC-22B

High breaking capacity

V0 class fireproofing

You can review our article Load Disconnectors : Safe Disconnection and Control in Electrical Circuits and get detailed information.

Load Disconnectors: Safe Separation and Control

Load breakersare devices that provide safe separation and control in electrical circuits. These devices prevent possible accidents and damages by safely separating the circuit in dangerous situations such as overvoltage and high current in electrical systems. The main function of load breakers is to safely separate the electrical circuit without interrupting the energy. They provide a safe environment without stopping the energy flow, especially during maintenance and repair operations.

Load breakers are widely used in industrial facilities, commercial buildings and energy production centers. These devices are activated especially in overcurrent situations that may occur in large energy lines, ensuring the smooth operation of electrical systems. They also allow circuits to be separated without interrupting the flow of electricity in high voltage lines.

Load breakers provide operators with the opportunity to work safely on the circuit. Operations performed without interrupting the flow of electricity both increase safety and minimize energy interruptions. In this way, operational processes can continue uninterrupted. While load breakers increase energy efficiency, they also prevent serious malfunctions that may occur in the system.

It is of great importance to correctly select and properly install the load breakers used in energy systems. These devices, which are determined according to high current and voltage requirements, enable a safe distribution of electricity. An incorrectly selected load switch may prevent the system from operating or may cause serious damage to the devices. Therefore, the installation and periodic maintenance of load switches must be carried out regularly. In order to ensure safe energy flow, it is necessary to ensure that the load switches perform their functions.

Types and Usage Areas of Load Separators

Load breakers are manufactured in various types according to different electrical requirements. These devices may have different functional features depending on the needs of the area used and the circuit. They can be generally classified under two main headings as manual and automatic load breakers. Manual load breakers are controlled manually by operators, while automatic load breakers automatically separate the circuit by detecting the changes occurring in the circuit.

Manual load breakers are generally used in small and medium-sized industrial applications. These devices are preferred due to their simple structure and low cost. The operator’s ability to control the circuit manually provides flexibility in the system. Automatic load breakers are preferred in larger and more complex energy systems. The use of automatic load breakers, especially in high voltage lines, is of critical importance in terms of preventing possible accidents.

Load breakers are used in energy production and distribution centers, industrial facilities, commercial buildings and high voltage lines. These devices, which have different features for each area of use, offer solutions to increase safety and efficiency in the system. Load breakers play a vital role in systems with high current and voltage values.

In addition, load breakers can be classified as closed and open type according to the application area. Closed type load breakers are more resistant to adverse weather conditions and environmental effects from the outside environment. Open type breakers are generally used in indoor environments and have a simpler structure. Both types play a critical role in ensuring energy security in certain areas of use.

Maintenance and Repair of Load Disconnectors

Regular maintenance and repair of load breakers is critical for the safe and efficient operation of electrical systems. Wear and tear or deterioration of these devices over time can jeopardize the safety of the system. Regular inspection of load breakers

and rapid elimination of possible faults ensures the trouble-free operation of the system. In cases where maintenance is not performed, improper operation of load breakers can lead to serious electrical accidents and system faults. Periodic maintenance operations increase the safety and durability of load breakers. During this maintenance, the mechanical and electrical parts of the devices are checked, loose connections are tightened and necessary lubrication operations are performed. In addition, it is very important to check the electrical insulation of the device. Since load breakers used in high voltage lines can be affected by environmental conditions, devices used in outdoor environments may need to be maintained more frequently.

Repair operations are usually carried out after the fault is detected. During this process, faulty parts may need to be replaced or reconfigured. During repair operations, the system should be de-energized and it should be ensured that the device is completely safe. Although load breakers are generally durable devices, regular maintenance and correct repair applications extend the life of the device and ensure the safe operation of the system.

Impact of Load Disconnectors on Energy Efficiency

Load breakers not only provide safety, but also offer significant advantages in terms of energy efficiency. The ability to separate circuits without interrupting the energy flow reduces energy losses and increases efficiency in the system. Especially in large energy systems, losses that may occur during the opening and closing of the circuit can increase energy costs. Load breakers help minimize these losses.

In industrial facilities, energy efficiency is one of the most important factors affecting the costs and overall performance of the business. Correct use of load breakers increases efficiency by preventing energy losses in the system. In addition, thanks to the ability to separate the circuit without interrupting the energy during maintenance and repair processes, there are no disruptions in the operating process. This increases productivity by maintaining business continuity.

Another energy efficiency contribution of load breakers is that they optimize energy use by preventing excessive current or voltage situations in the system. Energy waste may occur in overloaded systems, and this reduces the performance of the devices. Load breakers prevent such situations and ensure that energy consumption is balanced and efficient. Therefore, load breakers play a critical role not only in terms of safety but also in terms of saving energy.

Importance of Load Disconnectors in Industry

In industrial facilities, energy safety and efficiency are one of the most critical factors for businesses to be successful. Load breakers are the basic equipment used to ensure this safety. Especially in large-scale industrial facilities, continuous and safe operation of electrical systems is vital. Load breakers prevent damage to the system by safely separating the circuit in cases such as overcurrent or short circuit that may occur in these systems.

Load breakers also play a critical role in maintenance and repair processes. These devices provide business continuity by allowing the circuit to be safely separated without stopping the flow of energy. In industrial production facilities, energy outages can lead to major financial losses. Load breakers minimize energy outages and ensure that the workflow continues uninterrupted.

In addition, the fact that load breakers can be activated automatically increases system safety by reducing operator errors. Automatic load breakers, which detect dangerous situations in the system without the need for manual intervention, quickly separate the circuit and prevent possible accidents. This once again reveals how important the use of load breakers is in industrial applications.