Technical Specifications :

XMC 9A – 220A for 0.1A – 240A (progressive setting range)

XLC 9A – 800A for 1.6A – 630A (progressive setting range)

XMC M mini contactor 6A – 16A for 0.1-16A (progressive setting range)

What are Thermal Relays?

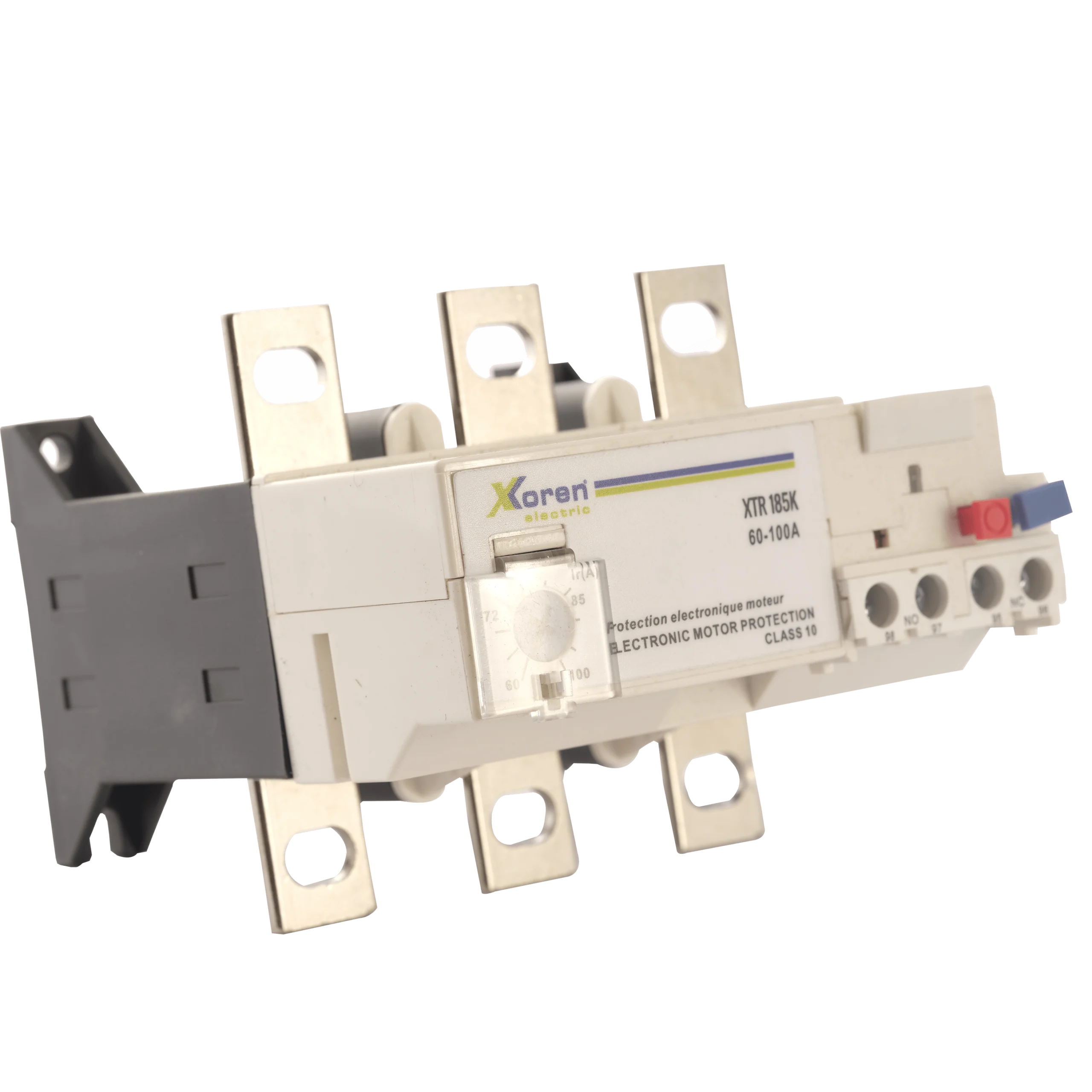

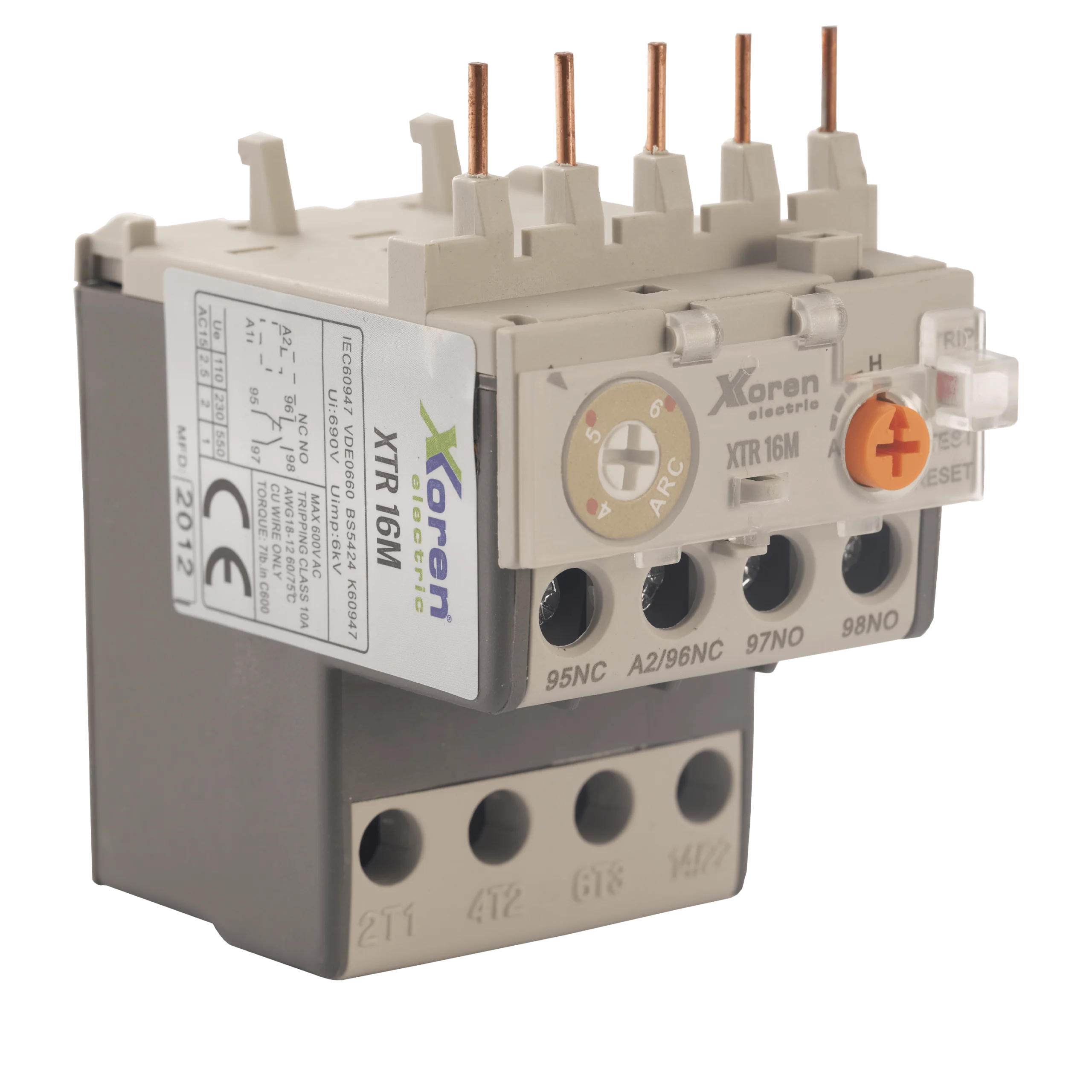

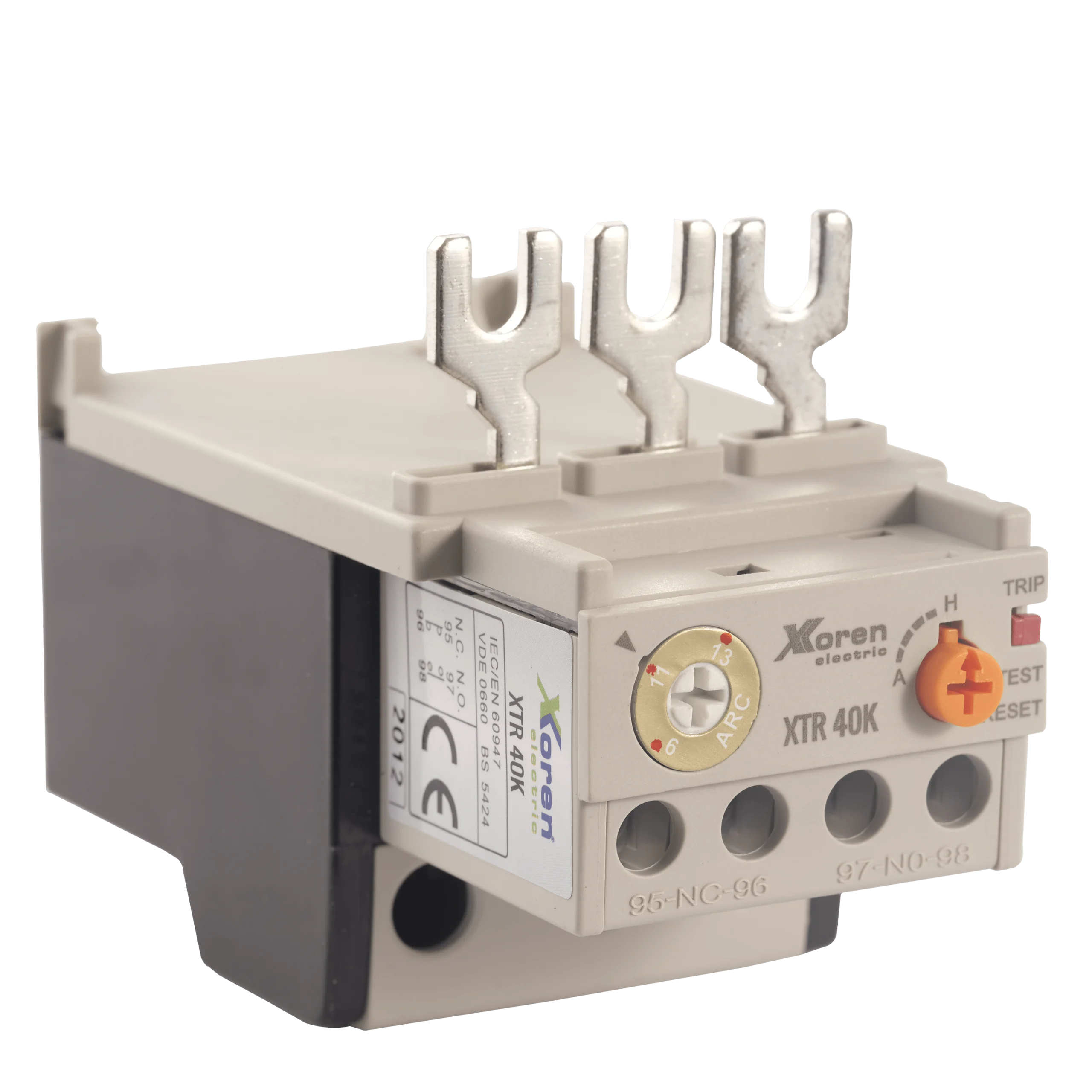

What is a thermal relay ? It is an electrical protection device designed to protect electric motors and other electrical circuits against excessive current and overload. Overcurrent is a current that exceeds the safe amount of current that an electrical circuit or device can draw and can cause the motor to overheat, damage or cause a fire. Thermal relays come into play to prevent this situation. Thermal relays are devices that operate using bimetallic elements and cut off the circuit when they detect excessive current in the circuit. This process protects the motor or circuit from overheating.

Thermal relays are widely used in industrial and commercial applications. They are developed specifically to provide protection for electric motors. They prevent damage to the motor by cutting the circuit in cases of overload that may occur during long-term operation of the motor. The operating principle is to monitor whether the current drawn by the motor is above the specified limits and to cut the motor circuit if these limits are exceeded. The bimetallic element inside the relay bends when heated due to excessive current and as a result of this bending, an open occurs in the circuit, i.e. the motor power is cut off. This process allows the thermal relay to protect the motor from burning or serious damage.

One of the most important advantages of a thermal relay is that it is a low-cost and easy-to-install device, in addition to protecting the motor against overcurrent. In addition, thermal relays are generally known as maintenance-free devices. Thermal relays play a major role in protecting expensive and critical equipment such as electric motors. They provide both safety and prevent costly failures by cutting the circuit in cases of overcurrent or short circuits.

The correct selection of thermal relays is also important. A thermal relay suitable for the current capacity required by the electric motor or circuit should be selected. Otherwise, a wrong thermal relay selection may cause the motor not to be protected or unnecessary circuit interruptions. For more information, you can check out the blog post titled What are thermal relays ?

Thermal Relay: A Vital Protection Device for Electric Motors

Electric motors are critical components of industrial manufacturing processes and are often operated for long hours. However, these motors can be sensitive to overload and excessive current. This is where thermal relays come into play. Thermal relays prevent the motor from burning out or being seriously damaged by interrupting the circuit when the motor draws excessive current. Excessive current causes the motor to draw more energy than it can handle, which can cause the motor to overheat and eventually fail. Thermal relays act as a fuse that ensures the motor operates safely.

The working principle of thermal relays is to monitor the current drawn by the motor and to cut the motor out if it exceeds a certain current limit. The bimetallic elements in the thermal relay heat up when excessive current passes and as a result of this heating, they bend and open the circuit. This mechanism prevents the motor from overheating, preventing larger faults and costly repairs. The protection of electric motors is one of the most important tasks of thermal relays in industrial applications.

The motor protection function of thermal relays is not limited to overcurrent. It also protects the motor by disabling it in cases such as when the motor operates under excessive load for a long time. For example, if there is a mechanical problem in the system where a motor is operating and this problem causes the motor to draw more power, the thermal relay is activated and shuts down the motor. This both ensures a longer life for the motor and reduces operating costs.

The protection of electric motors is of great importance for businesses to maintain their continuous operating capacity. Motor failures can interrupt the production process, which can lead to production loss. Thermal relays prevent such failures and ensure that businesses operate continuously and safely. You can click on the relevant blog post to learn more about thermal relays.

What is the Use of a Thermal Relay?

Thermal relays are devices used to protect electric motors and other electrical equipment against excessive current and overload. So, what exactly do thermal relays do? An electrical circuit or motor is designed to operate at a certain current capacity under normal conditions. However, if the current drawn by the motor increases due to overload, short circuit or other problem, the motor can overheat and become damaged. Thermal relays are activated to prevent damage that may arise from such situations.

The main function of thermal relays is to ensure that electric motors operate safely in situations such as overcurrent and overload. If the current drawn by the motor exceeds the specified limits, the thermal relay is activated and shuts down the motor, preventing excessive current from damaging the motor. Especially in industrial facilities, where motors are constantly operating, the use of thermal relays extends the life of the motor and ensures its safe operation.

Thermal relays continuously monitor the current in the electrical circuit and check whether the motor is operating within a safe range. If the motor operates under excessive load for a long time, the thermal relay opens the circuit and stops the motor. This prevents the motor from burning or suffering major damage. The protection of electric motors is of vital importance for the production processes to continue efficiently and without interruption.

Thermal relays are also easy to use and maintain. Correctly setting the relay can prevent possible failures by determining the current limits at which the motor will operate. Thermal relays play an indispensable role in ensuring that businesses have a safe production process and that their equipment has a long life. You can visit the relevant blog post to learn more about the areas of use and functions of thermal relays.

Thermal Relay Prices, Selection Criteria and Market Situation

Thermal relay pricesmay vary depending on factors such as the quality of the materials used, capacity, brand and model. The prices of thermal relays used in industrial electrical systems may be higher than those used at home. This is because industrial motors operate at higher power levels and require more protection. Thermal relay types available on the market are specially manufactured for different motor types and power capacities.

There are a few important criteria to consider when purchasing a thermal relay. First, a relay that is suitable for the power capacity of the motor to be protected should be selected. In addition, attention should be paid to the installation method of the thermal relay and whether it is compatible with the environment in which it is used. Although the price difference usually varies from brand to brand, higher priced thermal relays can usually be more durable and reliable. A quality thermal relay not only protects the electric motor, but can also reduce maintenance costs.

When examining the prices of thermal relays in the market, it can be seen that the prices of the most preferred brands are slightly higher than others. However, this price difference can be offset by the safety provided by the thermal relay and the savings it provides in the long term. Especially in large industrial facilities, the use of quality thermal relays minimizes the risk of failure and ensures that the production process continues uninterrupted. You can review the relevant blog post for more information about the prices of thermal relays and selection criteria.

Thermal Relays and Areas of Use

Thermal relays and their areas of use are widely used in various industrial motor systems. They provide safe operation by protecting electric motors in the event of overcurrent. These relays are generally preferred to prevent overloads in electrical circuits and offer great advantages in the long term when selected correctly.

Thermal relays have a wide range of uses. They are used to increase safety and efficiency in many different sectors such as the automotive industry, manufacturing facilities, and power plants. Thermal relays, which are suitable for different engine capacities, can be customized according to their areas of use.

Maintenance and Troubleshooting Methods of Thermal Relays

Maintenance and troubleshooting methods of thermal relays Regular maintenance is critical to extending the life of the device and operating electric motors safely. During maintenance, thermal relays should be checked for problems such as overload, mechanical wear and contamination.

During fault detection, the temperature ratings and current limits of thermal relays should be taken into consideration. Thermal relays protect the motor by cutting the circuit when exposed to excessive current for a certain period of time, but correct detection of faults in the relay ensures safe operation of the motor.

The Role of Thermal Relays in Industry

Thermal relays play a major role in the industry. They protect electric motors against hazards such as overcurrent and short circuits, ensuring an uninterrupted workflow in production processes.

The use of thermal relays in industrial facilities is important in terms of extending the life of motors, reducing maintenance costs and minimizing the risk of failure. Thermal relays are a key part of ensuring the safe operation of large motor systems in particular.