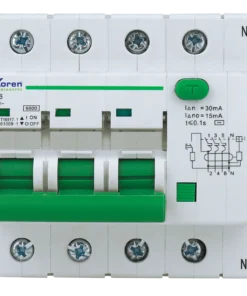

Technical Specifications:

Number of Poles: 3P

Rated Voltage: 690V

Rated Current: Up to 80A

Thermal Adjustment Range: 0.1A – 80A (progressive adjustment range)

Motor Operating Power: 32K model up to 15kW, 80K model up to 40kW motors

Motor Protection Switch Enclosure Box :

X Koren Electric Motor Protection Switch Accessory Enclosure Box; They protect electrical connections against adverse weather conditions and prevent electric shocks. Switch enclosure boxes made of plastic or aluminum material protect the motor protection switch against adverse conditions that may cause danger and provide insulation.

Protection against dust, water, various chemicals, explosive and flammable substances

High resistance to acidic, oily, dirty, rusty environments

Protection against UV rays

Protection Class: IP55

Waterproof

Warning with emergency button

What are Motor Protection Switches?

Motor protection switches, are important devices that protect electric motors against situations such as overcurrent, short circuit and overload. Electric motors can sometimes be exposed to such risks, especially in industrial facilities, because they operate with high currents. These switches ensure that the motor operates safely and are disabled in case of any danger and protect the motor. These devices, which are widely used in the industry, are also frequently encountered in commercial applications. Motor protection switches are activated in cases of problems such as overvoltage, phase loss and low voltage, preventing damage to the motor. Since motors are used in many different sectors, they are among the equipment expected to be resistant to faults. However, if this equipment is not protected correctly, it can lead to serious faults and financial losses. The main purpose of motor protection switches is to ensure that the motor operates smoothly and safely. These devices protect the motor against adverse situations such as overcurrent, short circuit and overload, while also extending the life of the motor. Motor protection switches consist of different mechanical and electrical components. They contain thermal and magnetic protection units. Thermal protection prevents the motor from overheating, while magnetic protection protects the motor against short circuits. The thermal unit constantly monitors the temperature level of the motor and protects the motor by opening the circuit when it exceeds a certain temperature level. Magnetic protection, on the other hand, reacts quickly to sudden and high currents that may occur in the circuit and cuts the circuit and prevents damage to the motor in the event of a short circuit. Motor protection switches, especially used in industrial motors, offer solutions to increase energy efficiency. If the motor itself is not disconnected in case of overload, the motor may be seriously damaged and its repair may be costly. Motor protection switches provide great security in order to minimize such risks. The areas of use of motor protection switches are wide. These switches, which are frequently preferred in large motors used in sectors such as construction, production and mining, have various capacities from small motors to large industrial motors. They are usually mounted on electrical panels and automatically activate to prevent damage to the motor by monitoring the electrical circuit. In addition, motor protection switches contribute to energy saving with the advantages they provide in the environment where the motor is operating. The fact that motors can operate continuously without failure ensures that work processes continue uninterrupted. This is a great advantage for businesses in terms of both energy efficiency and cost. The selection of motor protection switches should be made according to the type of motor and the area of use. An incorrectly selected switch will not protect the motor and may cause the motor to cause larger faults. Therefore,When choosing a motor protection switch, the power of the motor, the working environment and possible hazards should be taken into consideration. At the same time, periodic maintenance and checks should be done regularly, and the safety of the motor should be ensured in the event of any malfunction.

How Do Motor Protection Switches Work?

Where are motor protection switches used? It works on a simple but effective principle. It constantly monitors the current in the electrical circuit and cuts off the circuit to protect the motor when it detects an abnormal situation. These devices have been developed to protect the motor from possible dangers such as overcurrent, overload, short circuit and phase failure. Motor protection switches have thermal and magnetic protection features. Thermal protection prevents the motor from overheating. Operating the motor with high currents for a long time can cause the windings inside to overheat and this can shorten the life of the motor. The thermal protection unit monitors the temperature level of the motor and protects the motor by opening the circuit when it exceeds a certain temperature. Magnetic protection protects the motor against short circuits. When sudden and high current occurs in the electrical circuit, the magnetic protection is activated and quickly cuts off the circuit. This prevents the motor from being damaged due to short circuit. Magnetic protection usually works together with the short circuit protection circuit in electrical panels. Motor protection switches monitor the amount of current in the motor’s circuit and automatically cut off the circuit when it exceeds a certain level. For example, if a motor has a nominal current of 20 amps and this current exceeds 25 amps, the motor protection switch prevents the motor from being damaged under excessive load by interrupting the circuit. In this way, motor damage and costly repairs are prevented. Motor protection switches can also detect phase faults. In a three-phase electric motor, the risk of damage to the motor is quite high if any phase breaks or voltage drops. The motor protection switch detects such phase faults and disconnects the motor. This extends the life of the motor and minimizes the risk of failure. Motor protection switches are frequently used in modern automation systems. These devices ensure that electric motors operate efficiently and safely, while also contributing to energy efficiency. In automation systems, motor protection switches make it easier to monitor and control motors. The use of motor protection switches provides a great security advantage for businesses in addition to saving energy. Providing suitable solutions for large and small motors, these devices ensure that motors operate safely, minimizing interruptions in work processes. As a result, the working principle of motor protection switches is based on protecting the motor against dangers by monitoring the current in the electrical circuit. These devices detect situations such as overcurrent, short circuit and phase failure in advance, thus enabling the motor to be disconnected and extending the life of the motor.

What are the Technical Specifications of Motor Protection Switches?

Motor protection switches, are devices with advanced technical features designed to suit different motor types and areas of use. The technical features of these switches are very important to ensure safe and efficient operation of motors. First of all, it is necessary to look at the nominal current capacity of motor protection switches. Each motor protection switch is designed to operate within a certain current range. For example, a protection switch between 0.1-6 amperes may be sufficient for small motors, while switches with capacities of 100 amperes and above are used for large industrial motors. Another important feature of motor protection switches is their thermal and magnetic protection features. Thermal protection is a mechanism that prevents the motor from overheating. This protection constantly monitors the temperature level of the motor and cuts the circuit when it reaches a certain level. Magnetic protection is activated in short circuit situations. A short circuit causes very high currents to suddenly occur in the electrical circuit and the risk of damage to the motor arises. The magnetic protection unit detects these sudden currents and cuts the circuit to protect the motor. The operating voltage of motor protection switches is also an important technical feature. The operating voltage of the switches must be compatible with the operating voltage of the motor. Switches designed for low-voltage motors generally operate in the 230-400V range, while switches with capacities of 690V and above are used for high-voltage motors. Motor protection switches also have a phase fault detection feature. In three-phase motors, any phase breakage or voltage drop can cause the motor to operate unbalanced and malfunction. Motor protection switches that detect phase faults detect this situation and disable the motor and prevent malfunctions. Settings suitable for the nominal current of the motor can be made with the adjustment buttons on the switches. Making these settings correctly provides more sensitive protection of the motor against overcurrent and short circuits. For example, a setting between 9.5-10.5 amperes can be made for a 10 ampere motor. In this way, the switch cuts the circuit before the motor’s current limit is exceeded and damage to the motor is prevented. Another technical feature of motor protection switches is their mechanical durability. These devices are manufactured to maintain their durability even when exposed to long-term use and high currents. Designed using high-quality materials, these switches continue to protect motors safely even under difficult operating conditions. Finally, motor protection switches can be integrated into automation systems. This feature allows motors in large industrial facilities to be monitored and controlled via a central system. Automation systems monitor the operating status of the motors and, together with the data provided by the motor protection switches, ensure that the motors operate efficiently. All these technical features,shows that motor protection switches ensure safe and efficient operation by protecting motors from hazards such as overload, short circuit and phase failure. Correct selection and regular maintenance of motor protection switches extends the life of motors and also increases work safety.